BYWT sewage lifting equipment

The HYWT series device is a special equipment for underground sewage discharge, using the "split trash separator device" to avoid clogging sewage and sundries in the winding of the pump, the sewage discharge under the sealed condition is more excellent for environmental protection, the device has a backwash function. To solve the problem timely and necessary cleaning due to precipitation dirt, to avoid the drawbacks encountered in the process of using the traditional sewage pump.

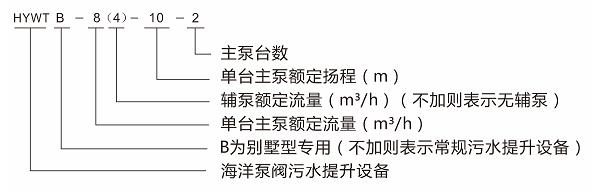

Model significance

Product features

Non clogging

The use of unique pollution discharge technology, water pump impeller does not touch the debris, will not cause winding and clogging, can extend the service life of the pump.

No precipitation, no clearance

The utility model realizes the separation technology of the sundries and the sewage, and uses the pressure of the water pump to discharge the sewage, and discharges the waste. The utility model has the function of back flushing, and solves the problem that the sludge must be cleared in time.

Pollution-free

Fully enclosed design, no overflow, no odor, protect the surrounding environment.

Remote monitoring (optional)

According to customer needs, optional equipment remote monitoring system, the personnel on duty at home, an intuitive understanding of the running state of the equipment.

Reduce area

Equipment covers an area of small, flexible installation, saving the cost of civil engineering investment, reduce costs.

Functional characteristics

HYWT series of equipment is a collection of sewage collection, isolation, liquid level control, to enhance emissions in the integrated equipment, it has the following characteristics:

Manual / automatic function:

In the manual operation of the state, you can operate any pump work, when the water level reaches the lowest design level, still can automatically stop running;

In the automatic mode, the water level reaches the set limit, automatic pump drainage, water level is lower than the set threshold, automatically shut off the pump to stop the drainage, two pumps operate alternately, standby each other; when a sewage pump failure, the equipment can automatically switch to another sewage pump, and fault alarm prompt.

Sewage separator structure with unique sundries:

The debris sewage separator structure, water and debris can be wound without contact, avoid clogging debris around the pump impeller and pump motor burned; with backwashing function, the device will not produce precipitation, realizes no precipitation, free cleaning, greatly reduce the cost of equipment operation and maintenance management.

No water in basement:

When there is a certain position in the pit of the basement, the equipment will automatically start the auxiliary pump and discharge the sewage.

Control characteristics

The two pumps operate alternately and low level and high level to stop the pump to start the pump and other functions, can also pump fault, fault phase and phase error protection, fault alarm. The device can realize automatic and manual control.

Automatic operation of single pump -- automatic switching of single pump failure.

When the pump failure, the program will automatically turn the device into a "single pump operating state"; when the pump repair, thermal protection reset, the system will automatically return to the "double pump automatic operation" state.

HYWT series underground sewage equipment is equipped with liquid level floating ball (electronic liquid level sensor). Liquid level float ball (electronic liquid level sensor selection) with "pump level", "stop pump level" two water level detection points, can accurately control the 2 pumps running alternately.

Through data lines, the running state of the equipment required by the user of all kinds of signals are transmitted to the control room, the staff on duty at home, on a monitor screen to intuitively understand the running state of the equipment, nip in the bud.

Use scope

Sewage discharge from basement kitchen and toilet.

Underground shopping malls, restaurants, beaches and other services in the field of sewage discharge.

Subway station, underground corridor and other sewage discharge.

In the urban area, small unmanned operation sewage pumping station.

Large scale pharmaceutical, telecommunications, hospitals and other large institutions of sewage discharge.

Use conditions

Power frequency 50HZ, three-phase AC 380V, single-phase 220V.

The waste water (including flexible sundries and solid particles) must be able to flow in the pipeline.

Sewage temperature is not more than 40 DEG C, pH value of 4-10, sewage density of 1200Kg/m3.

The humidity of the control cabinet shall not exceed 80%.

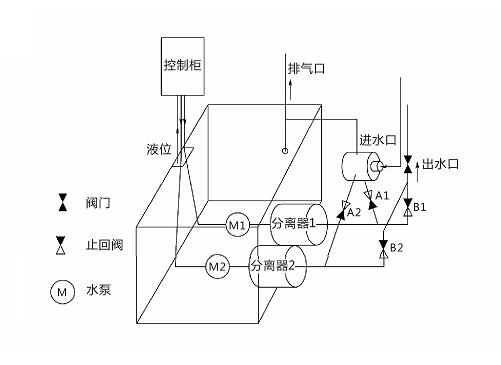

Drainage diagram

Equipment operation flow

The wastewater containing impurities from the water inlet into the water four, and then through the check valve, then enter the cyclone separator after filtering the sewage flows into the water tank. At this time, the impurities in the sewage are temporarily separated from the separator after being filtered and separated.

When the water level of the water tank is set to a high level, the work of the level meter is fed back to the control system, and the control system starts the M1 of the water pump. In this process, the use of A1 pump discharge of sewage pressure, close the valve, while opening the check valve B1 valve, the separator will temporarily exist in the dirt with the sewage discharge 1;

At the same time as the water pump M1, separator 1, check valve A1 and B1 piping system, the check valve A2 pipeline system continues to flow into the sewage and separated by the separator 2;

When the water in the tank is discharged to a low position, the water pump M1 stops working, and the check valve A1 valve opens to start to accept the inflow of sewage, check valve B1 valve closed to prevent the discharge of sewage reflux;

When the sewage once again reached the set of high position, the liquid level instrument will detect the signal back to the control system, the control system to start the water pump M2 start work. In this process, the use of pump drainage pressure, check valve A2 is closed, open the B2, at the same time will be temporarily stored within the dirt separator 2 discharged together with sewage pump; in M2, 2, check separator pipeline valves A2 and B2 at the same time, the check valve A1 piping system continues to flow into the sewage and by the 1 separate dirt separator;

When the water tank of the sewage discharged again to set low position when the pump stops the M2, the A2 valve open again started to accept the inflow of sewage, B2 valve closed to prevent discharge of sewage backflow;

In the process of drainage, the system controls the operation of two pumps alternately.

When the liquid level float (electronic sensor selection) detected water into the pit equipment, the system will start the auxiliary pump, sewage discharge, and alarm.