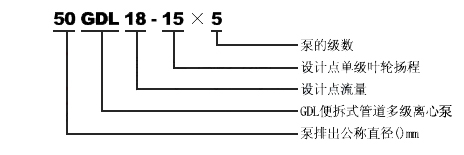

Model significance

Product profile

GDL vertical centrifugal pump is designed and manufactured with reference to advanced foreign products. Impeller, guide vane and guide shell are made of stainless steel plate by stamping, stretching and welding. Has the advantages of small size, light weight, high efficiency, energy saving, low noise, stable operation, long service life, vertical installation, covers an area of small, light weight and beautiful appearance and other characteristics, is the ideal update product.

Product features

1, GDL type vertical centrifugal pump for the vertical structure, with a small area of the characteristics of the pump center of gravity coincides with the center of the pump foot, which is stable, small vibration, long life.

2, GDL type vertical centrifugal pump diameter and the same level in the center line, without changing the pipe structure, can be directly installed in any part of the pipeline, the installation is very convenient.

3, plus the motor rainproof cover can be placed directly for outdoor use, without the construction of pumping stations, greatly saving infrastructure investment.

4, GDL type vertical centrifugal pump head can be changed by changing the pump series (impeller number) to meet the different requirements, so a wide range of applications.

5, seal with hard alloy mechanical seal, reliable sealing, no leakage, small mechanical loss.

6, high efficiency and energy saving, beautiful appearance.

7, the injection of more than 50 caliber castings.

Product use

GDL type vertical centrifugal pump is especially suitable for boiler feed water, also can be widely used in pressure vessel of water supply, water circulation, high-rise building water supply, irrigation, fire booster, hydraulic flushing, food, brewing, pharmaceutical, chemical industry, aquaculture, environmental protection, chemical process and machine industries, as the power device the water supply and drainage.

Use conditions

1, used to transport water or similar physical and chemical properties of water;

2, the liquid should be no solid particles, no fiber, no strong corrosion, no explosion hazard;

3, the maximum liquid temperature does not exceed 120 degrees c;

4, the maximum working pressure is not more than 2.5MPa;

5, power supply for the 3 phase 380V, 50HZ. Voltage fluctuations within + 5%;

6, the ambient temperature should be lower than 40 degrees, relative humidity is less than 95%.