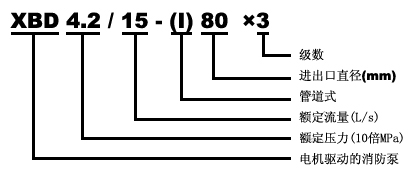

Model significance

Product introduction and features

On the basis of the original vertical multi-stage pump, a new generation of XBD pipeline type medium and low pressure fire pump group product is developed on the basis of the latest standards of fire pump. The series of pumps in the performance, structure, materials and matching to meet the requirements of fire pumps. Due to the excellent hydraulic model, so this series pump has to meet user requirements; the vertical structure has the characteristics of high efficiency, wide range of performance, can be good land area saving; high quality bearings and high quality motor, pump operation is safe and reliable, low noise, small vibration by; the hydraulic balance of axial force, reduce the balance drum, can make the operation more smoothly; the seal mechanical seal and packing seal in two forms; the pump also has import flange slobber pipeline arrangement, high speed, weight etc..

Application scope

The utility model is suitable for various occasions such as houses, hotels, office buildings, commercial buildings, factories, hospitals, etc..

Performance range

flow:5~115L/s

lift:20~230m

power:3~200KW

Working conditions

1, can be transported water or physical and chemical properties similar to the clear water of the corrosive medium, the solid insoluble matter not more than 0.1%.

2, medium temperature: -15 DEG C ~120 C.

3, the maximum working pressure: XBD type pump: less than 2.5MPa, the system pressure head + = 2.5MPa, XBD (I) type pump: less than 2.0MPa.

4, the ambient temperature is not more than 40 degrees, relative humidity is less than 95%.

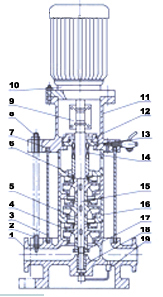

Schematic diagram and description

number | Name | material | number | Name | material | number | Name | material |

1 | Pump body |

| 8 | Nut | 45 | 15 | axis | 2Cr13 |

2 | Tension bolt |

| 9 | coupling | HT200 | 16 | Middle part | HY200 |

3 | Outer cylinder | ZG1Cr18Ni9Ti | 10 | Electric machinery |

| 17 | Sleeve nut |

|

4 | Impeller | HT200 | 11 | Connecting seat | HT200 | 18 | Bearing bush | QSA4-3 |

5 | Impeller gear sleeve |

| 12 | Seal seat |

| 19 | Return pipe |

|

6 | Axle sleeve | HT200 | 13 | Exhaust valve |

|

|

|

|

7 | A seal |

| 14 | Mechanical seal |

|

|

|

|

1, the pump is vertical, multi-stage structure, water pump inlet and LAN in the same line, the impeller adopts hydraulic balance force to balance axis, | ||||||||